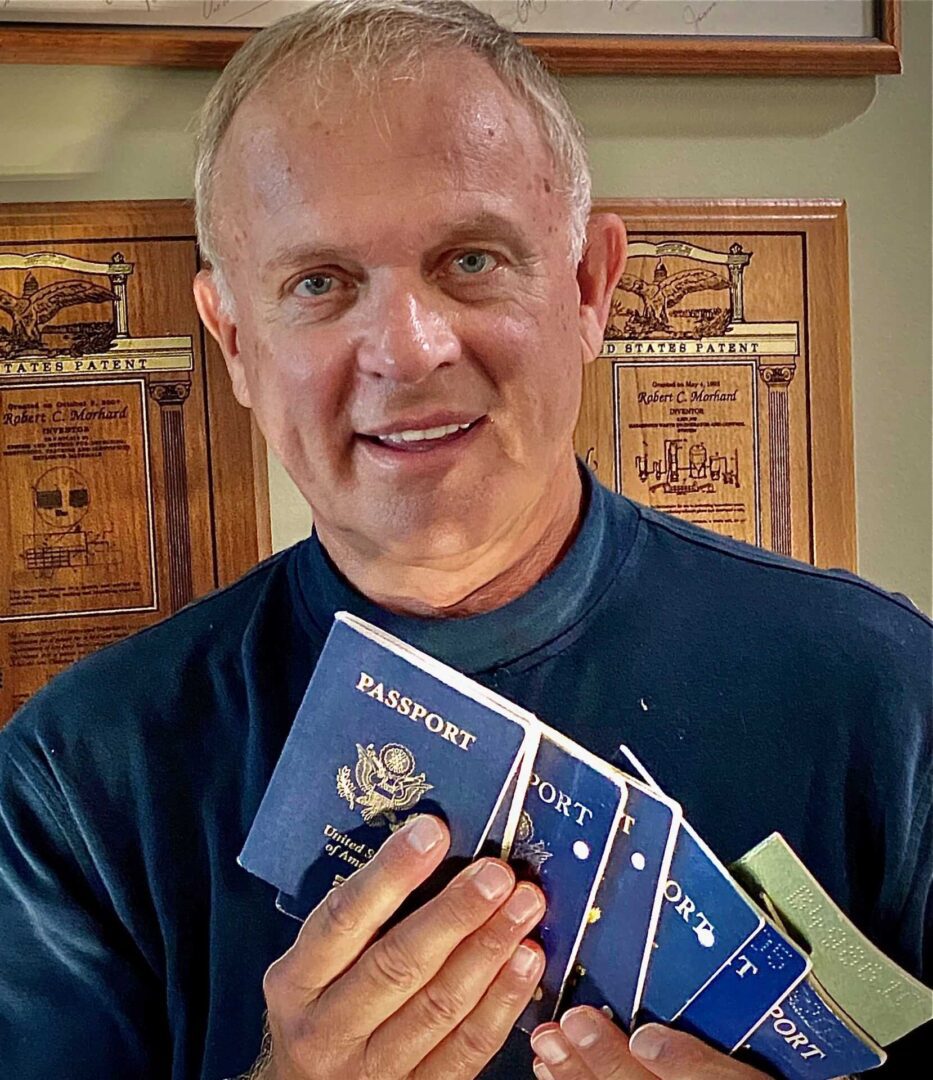

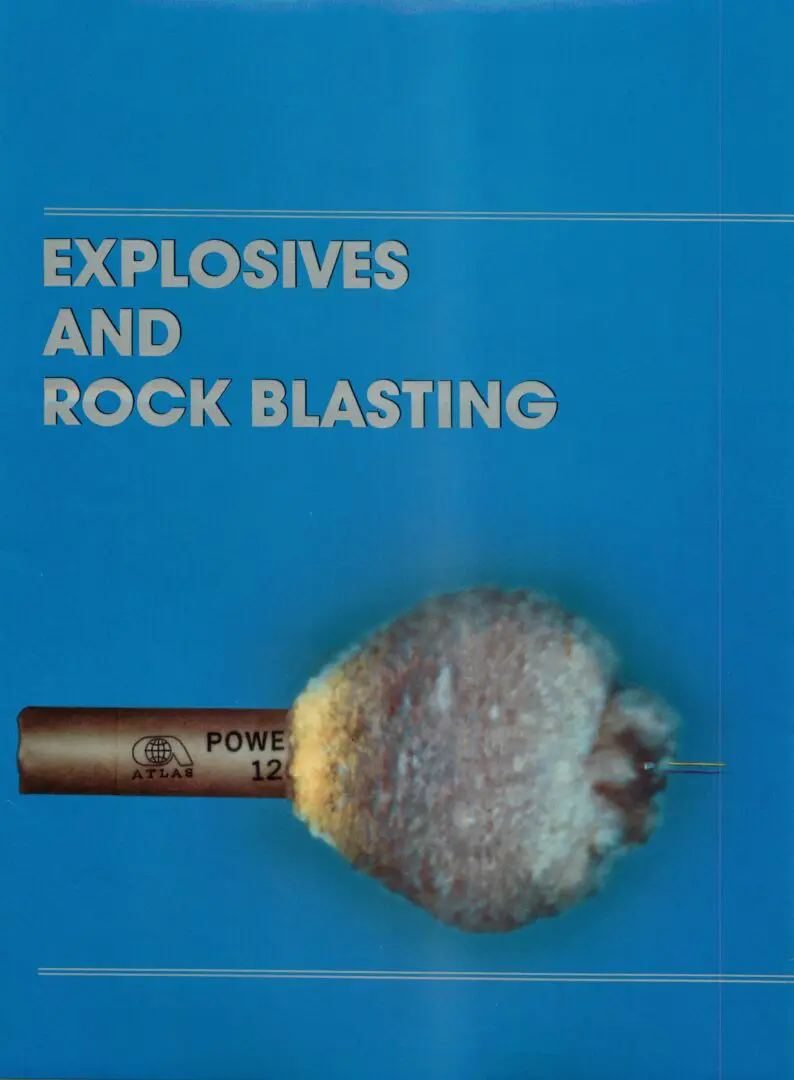

ExploConsult Solves Complex Problems

Qualifications

50 years of providing safe and efficient solutions related for the formulation, product development, processing, handling, storage, use, recycling and disposal of explosives, propellants and pyrotechnics supporting 745 projects in 110 countries worldwide.

The range of projects completed includes: research and development, raw materials approvals, formulation and chemistry, processing plant design and siting, regulatory approvals, UN and US DOT Hazardous Materials Certification, production processing, equipment design, procedure development, packaging design, handling, operator safety, risk-management, storage, logistics, use and application, insurance underwriting, accident investigation, life-cycle management, recycling and disposal.